Microwave

Elliptika

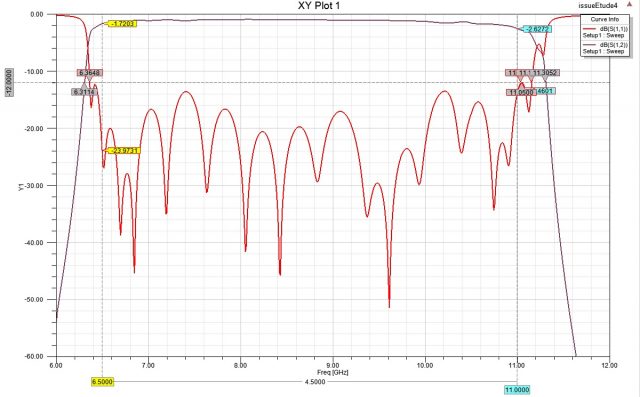

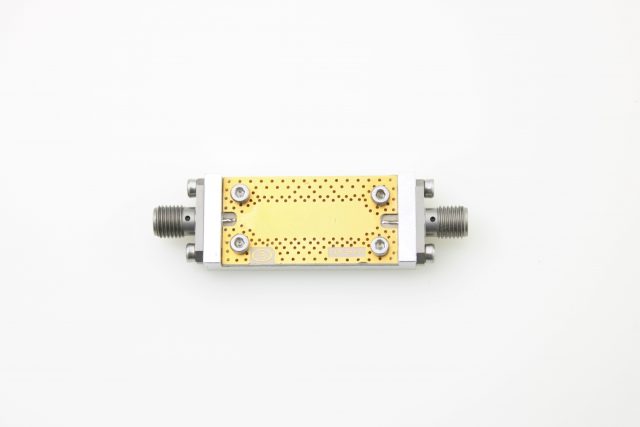

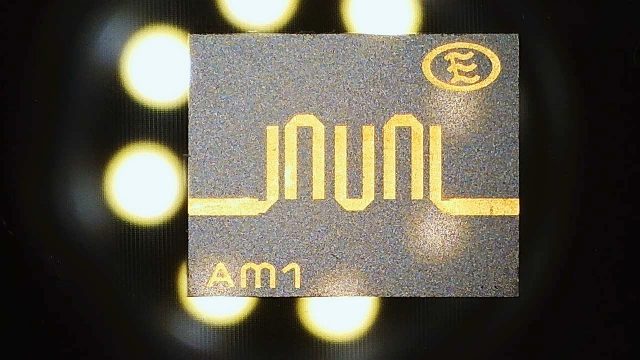

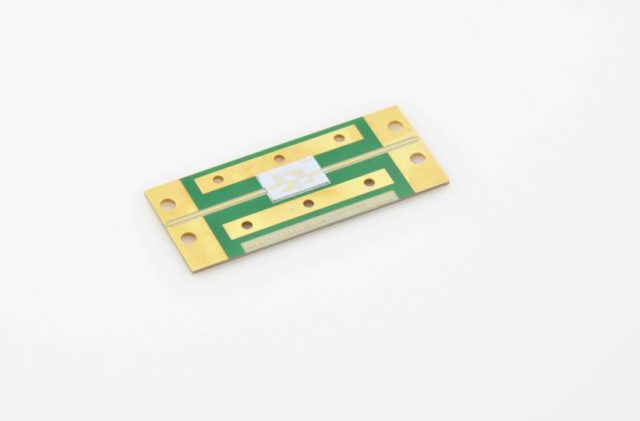

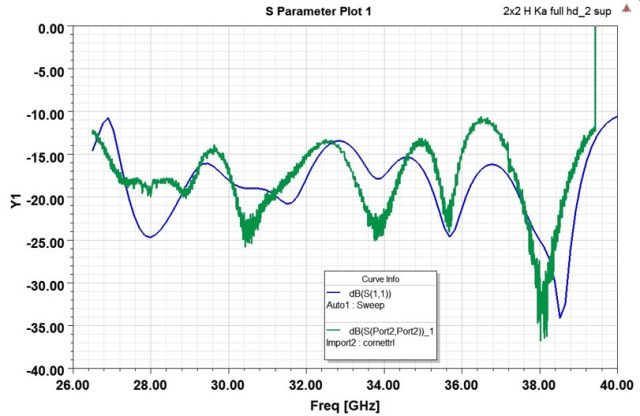

We use the most cutting-edge modeling software and syntheses on the market (ADS, Momentum, HFSS and Ansys Designer) to develop the solution that meets the best compromise between electrical performance, size, weight and cost. We also offer a design and production service for 3D printing parts and microwave components in plastic additive technology with total or selective metallization of the component. This technique makes it possible in particular to greatly reduce the weight, the cost and the manufacturing times.

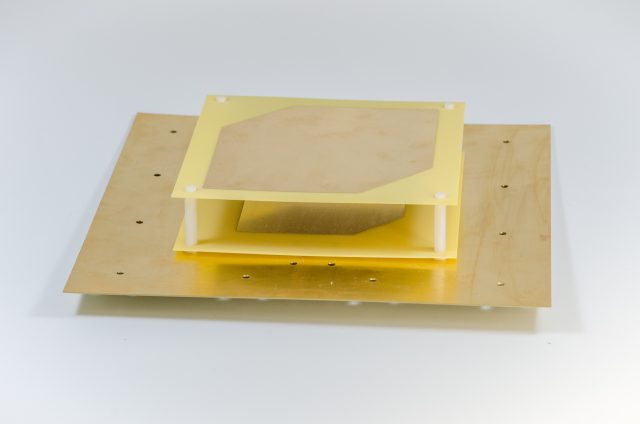

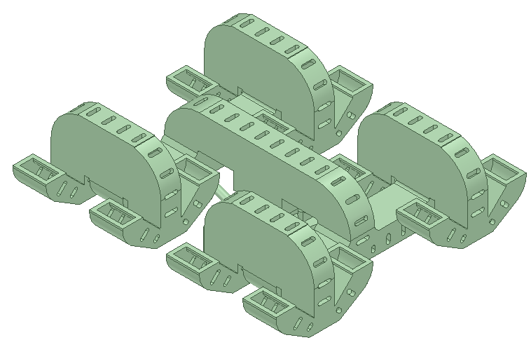

EXAMPLE 1

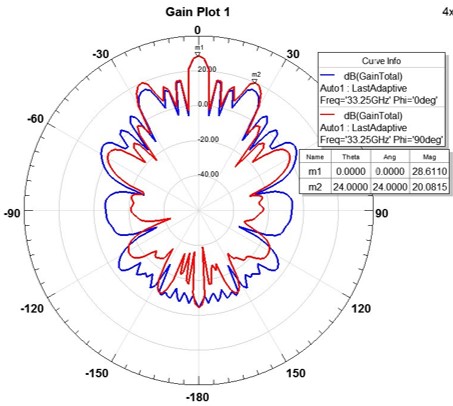

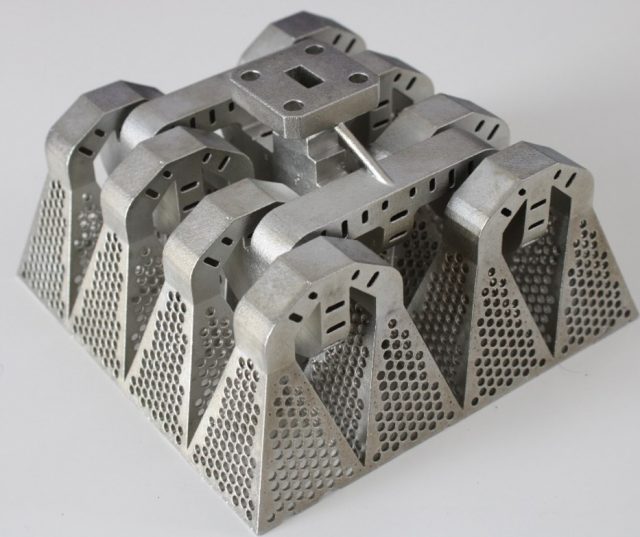

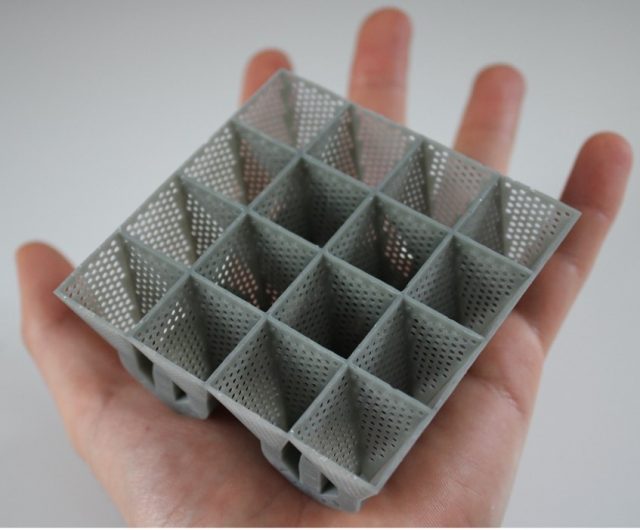

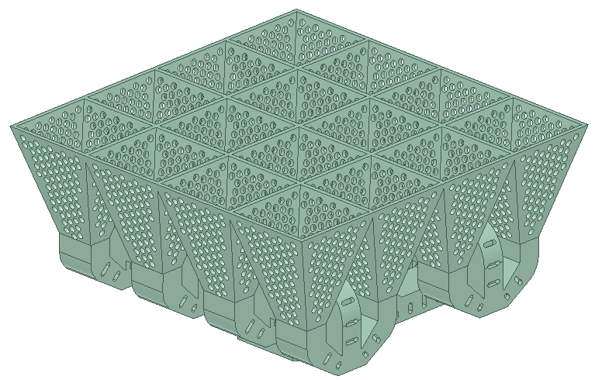

Here is the example of a 3D printing monobloc fabrication (SLA technology) of a 4×4 ka band antenna array made up of 16 horn antennas, and its 1 to 16 feed array.

Benefits of additive manufacturing :

The ELLIPTIKA additive manufacturing process made it possible to print this complex system in a single block, thus eliminating the assembly steps performed for these products.

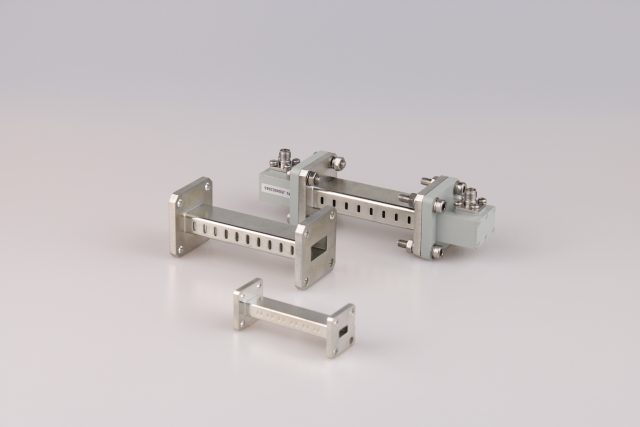

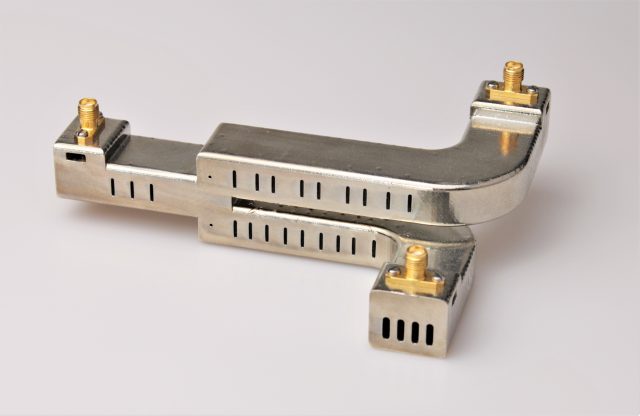

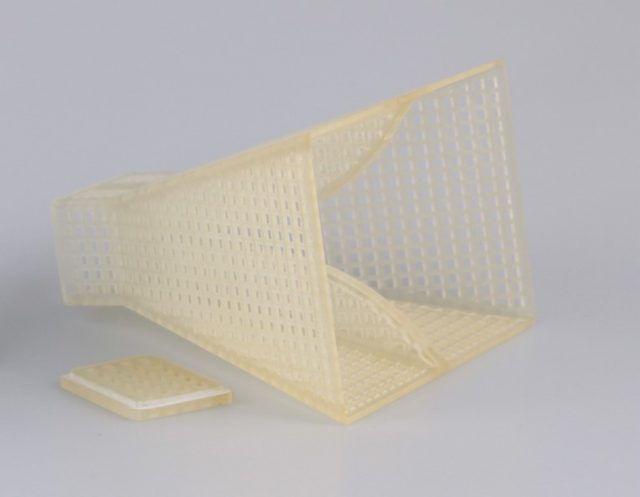

EXAMPLE 2

One-piece 3D printing (SLA technology) manufacturing of a highly lightened rigid double horn antenna, printed in high temperature resin.

Benefits of additive manufacturing :

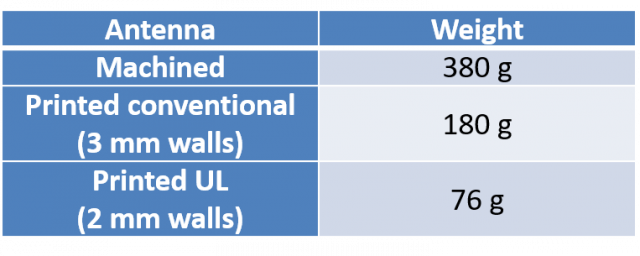

ELLIPTIKA’s work has made it possible to lighten the antenna, from 380g to 76g, while maintaining performance and temperature resistance up to 150 ° C.